Pioneer Labs is engineering microbes for Mars 🦠

Our mission is to create hardy critters that can make biomanufacturing robust, scalable and green — on Earth and beyond 🌎 🚀

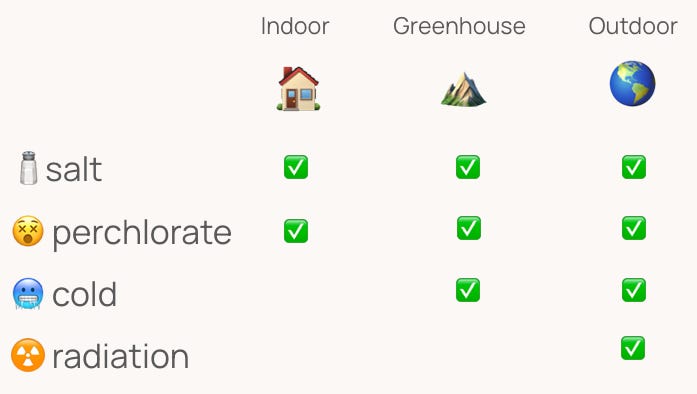

A microbe that could grow on Mars would need to tolerate many extreme conditions that would kill most microbes we’re familiar with on Earth. In particular:

🧂salt - The dirt (or regolith) on Mars is very salty.

😵 perchlorate - Martian regolith contains 0.5-4% perchlorate (ClO₄⁻), a chemical similar to bleach.

🥶 cold - Organisms on Mars would need to survive low temperatures and daily freeze-thaw cycles.

☢️ radiation - The surface radiation dose of UV-C on Mars is very high, at 3 W/m2.

A microbe growing outside on Mars must tolerate all of these extremes, which is quite the challenge! However, organisms can be partially shielded from the elements by growing them in indoor bioreactors or greenhouses. Doing so creates stepping stones toward a fully-outdoor organism, and is also independently useful for biomanufacturing and farming.

As a first step toward an outdoor Mars microbe, Pioneer Labs is engineering microbes optimized for indoor biomanufacturing on Mars. To do so, we are engineering commonly used chassis organisms E. coli and B. subtilis for in situ resource utilization (ISRU) on feedstocks containing Martian regolith. Regolith is a plentiful raw material on Mars that is a good source of nitrogen, but also contains high levels of salt and perchlorates are toxic to today’s chassis organisms. Our Marsified chassis microbes will unlock robust, scalable production of products like food, pharmaceuticals, and building materials for the first astronauts on the red planet.

How we’re doing it: Benchmarks 🏆, Measurements📏, and Cranks🛠

We’re breaking this task down into three steps:

Define a 🏆 Benchmark for Mars-readiness. Benchmarks are created in consultation with the broader space science and biotech communities. They synthesize key technical challenges into a measurable statistic.

Create assays to 📏 Measure performance of strains. We need robust wet lab techniques to quantify how different microbes perform in stressful conditions.

Engineer microbes that beat the benchmark! To do this, we need to create engineering methods where you can ‘turn the 🛠 Crank’ to generate new strains with improved properties.

We expect to repeat the 🏆 → 📏 → 🛠 process many times before we get to a green Mars!

Our first project

🏆 Develop the Indoor 0.0 Benchmark

We are currently roadmapping for Benchmark Indoor 0.0, designed to be an easy-to-understand and simple-to-execute test of suitability for indoor biomanufacturing on Mars. Like many biotech companies that want to incorporate a new low-cost feedstock into a manufacturing pipeline, we will approach this problem by quantifying the ratio of rich-media to Mars-regolith-containing-media that an organism can tolerate.

Get involved: we are looking for space scientists to provide feedback on our benchmark design, please reach out to indoor.0.0@pioneer-labs.org

📏 Create assays to measure salt and perchlorate tolerance

We are optimizing assays for quantifying the salt-tolerance and/or perchlorate-tolerance of a strain. This measurement technique needs to be feasible (reasonably fast + inexpensive to conduct) and also quantitative (gives you the same number, within error, when you measure it twice).

🛠 Engineer strains using functional genomics and directed evolution cranks

We are creating engineering pipelines for transferring extremophile properties between organisms. We are experimenting with a functional genomics approach in which we extract DNA from intractable extremophiles, insert that DNA into E. coli and B. subtilis, and select for microbes that exhibit improved extremophile properties as a result of the new DNA. We will compare the utility of this approach to good, old-fashioned serial passaging in the presence of a stressor. Meanwhile, we are developing bioinformatics approaches to make data-informed decisions about which organisms to work with and how best to evolve them.

We aim to focus on this first project between opening doors in April 2024 and mid-2025. Expect posts in the next couple of months elaborating on our initial results.

What’s next?

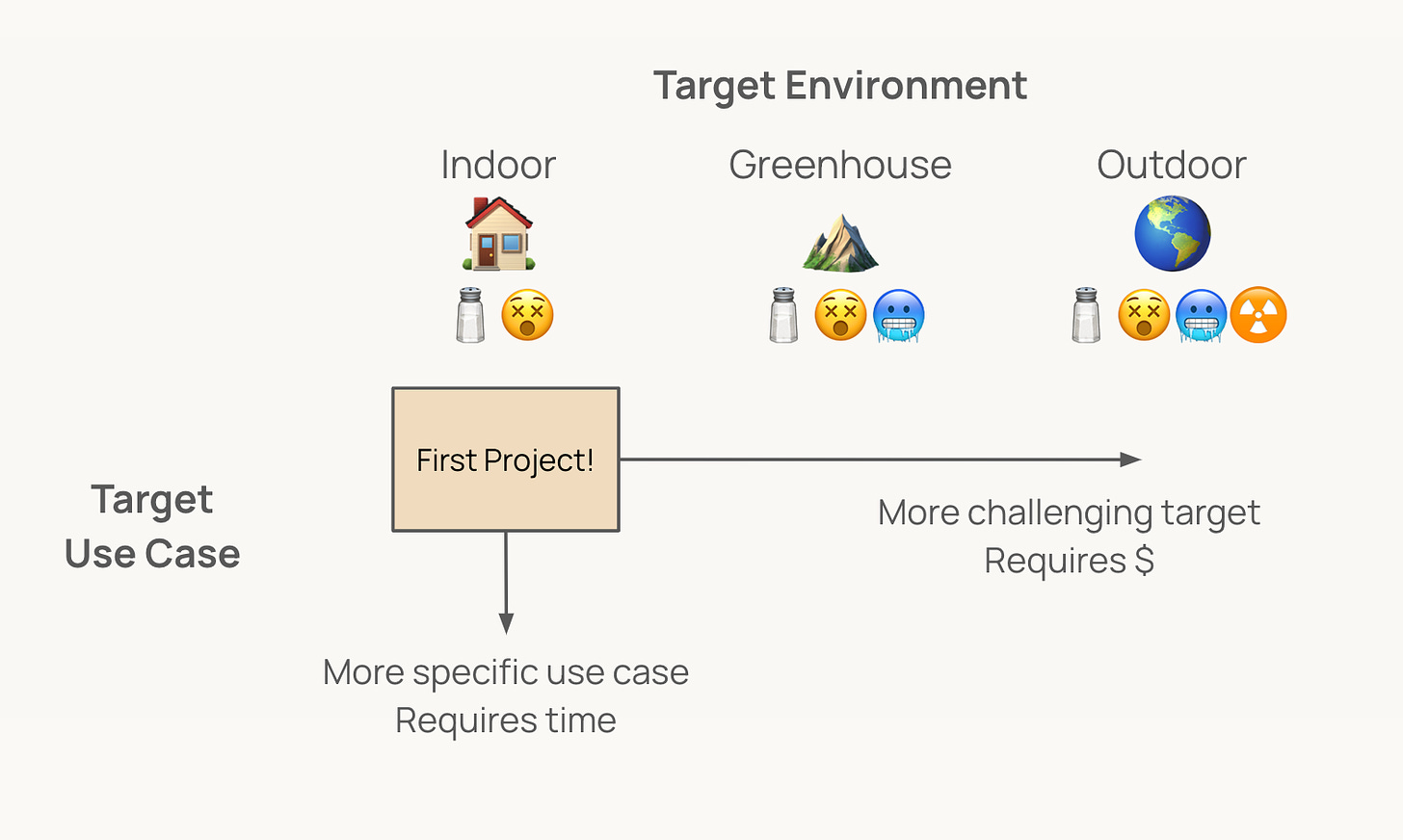

After the first project, we will expand in two directions.

Target more challenging environments on Mars, like growth in minimal greenhouses that experience daily freeze-thaw. These projects are currently $-constrained because they require funding for specialized equipment to simulate Mars-like extremes (low temperature, low pressure, radiation, etc) and funding to expand the team to work in non-model microbes.

Target biomass farming in Martian minimal greenhouses 🌽

Make a microbe capable of surviving and growing on the surface of Mars🌲

Target more specific use cases of extremophiles used ‘indoors’, both in space and on Earth. These projects are currently time-constrained because they require identifying, defining, and engineering toward a specific use case.

Simulate Martian ISRU conditions to a higher level of fidelity 🧑🚀

Target the specific application of manufacturing bioplastic on Mars from atmospheric carbon 🧑🚀

Expand our ISRU conditions to include the Moon 🌔

Develop solvent-tolerant microbes for industrial biotechnology on Earth 🌎

Follow along

We want to get feedback on our work faster than traditional scientific publishing will allow. That’s why we’re launching this substack, where we’ll post science updates. We’ll aim to keep the blog posts as easy reading, and may also link out to longer-form technical reports built from our lab notebooks. Follow along!

Read more about Pioneer Labs on our website, https://www.pioneer-labs.org/.

💬 Comments welcome

Place your bets now for which extreme will be hardest 🧂😵🥶☢️ to crack! What specific use cases for extremophile engineering would you want to see us tackle next? Comments welcome - discuss below: